Got a 140H kicking my butt!

2ZK prefix

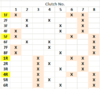

Machine only had 1F,5F,1R,4R. Machine will kinda spin the tires with them off the ground in other gears

No codes

All pressure ports test good and solenoids seem to be working

Transmission is a reman with less then 200hrs

Anybody have any ideas or something else I should check?

Also have removed screen and its look normal. Fluid is the right color and doesn't smell burnt.

Have access to SIS and ET

2ZK prefix

Machine only had 1F,5F,1R,4R. Machine will kinda spin the tires with them off the ground in other gears

No codes

All pressure ports test good and solenoids seem to be working

Transmission is a reman with less then 200hrs

Anybody have any ideas or something else I should check?

Also have removed screen and its look normal. Fluid is the right color and doesn't smell burnt.

Have access to SIS and ET