Hey all, here is a little update from over the weekend. Didn't get as much done as I hoped to becasue the weather here is WA state is going insane! It was close to 110 yesterday

For the record, the blue and red plugs that I showed are for the steering clutch compartments and you should def. drain all of them. I removed the blue plugs over the weekend and had a gallon of water come out of each. I kept flushing both sides through the trans dipstick filler neck until the fluid ran clear. I plan to re-drain everything once I get the old girl up and running and put her to work a little bit.

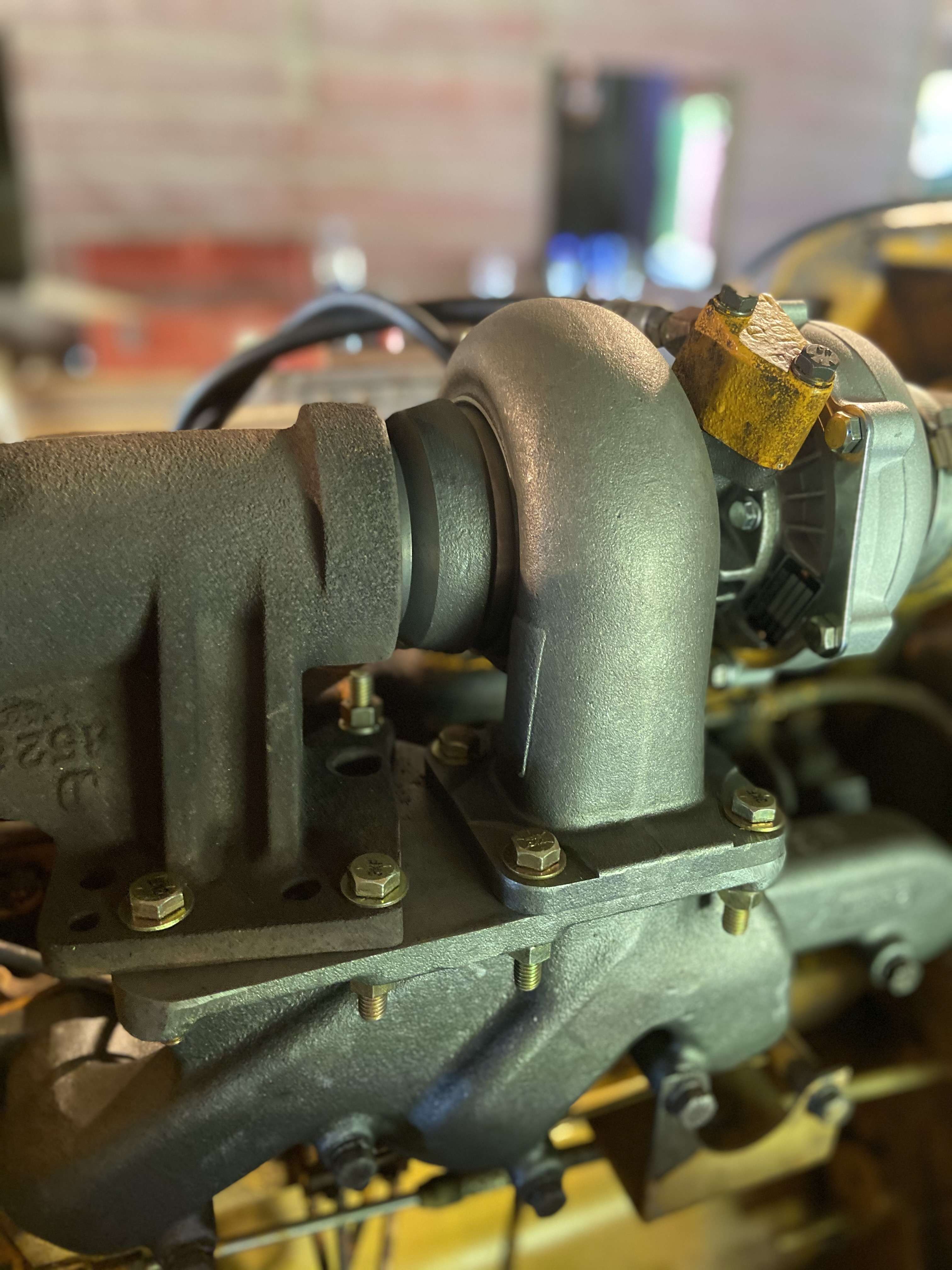

Check out my exhaust doughnut. Again it seems pretty loose to me

New seat assembly and armrests installed.

Newly rebuilt tilt cylinder installed and all new hydraulic hoses installed as well throughout the entire machine. Plus lots and lots of fine cleaning.

------------------------------------------------------------------------------------------

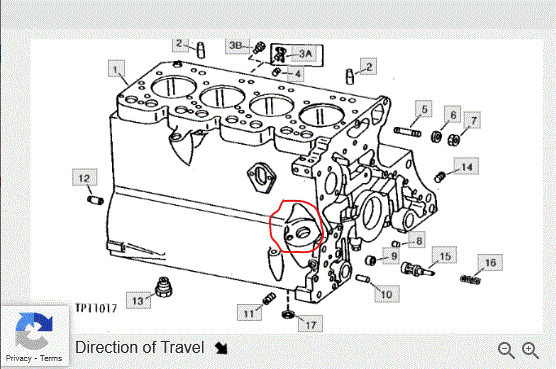

So I was able to get the machine to fire and run on Sunday. It was quite the job to get the fuel system bled, but I was able to get it done. Here is what I am dealing with now that I let the machine fire and run for maybe 20 mins or so.....I have an engine oil leak at the oil filter housing. When looking at JD parts it doesn't show any type of gasket between the oil filer housing assembly and the engine block? Does anyone know if there is a gasket in there? And if so, what is the part # for it? IF there isn't supposed to be a gasket, is an RTV product what I should use to seal this off?

Thanks everyone for all the help!