-

Thank you for visiting HeavyEquipmentForums.com! Our objective is to provide industry professionals a place to gather to exchange questions, answers and ideas. We welcome you to register using the "Register" icon at the top of the page. We'd appreciate any help you can offer in spreading the word of our new site. The more members that join, the bigger resource for all to enjoy. Thank you!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Hitachi Ex 100-2 very slow hydraulics

- Thread starter RPMex

- Start date

LACHAU

Senior Member

Hi RPMex,Certainly no rush I appreciate your time more than I can say!

Could I ask how is your machine now? What are the symptoms of your machine? Does it work slowly or overload it?

RPMex

Well-Known Member

Hi Lachau thank you so much for reaching out!!!

Currently the machine is overloaded. If I move any hydraulic function to fast or to max the machine will stall. I have an MPDr and below are my readings

delivery pressure 4.0-4.3

pump solenoids dn

Ap 23.9

Apr 4.6

DP - 2.6 MPa

when checking the voltage on the solenoids I get these readings

Solenoid #1 with key on engine off

Power (YB) - 24.70

Ground (RBL) - 24.42

Engine running at idle

Power 28.41

Ground 13.44

Solenoid #2 with key on engine off

Power (YB) - 24.45

Ground (Y) - 24.53

Engine running at idle

Power 28.49

Ground 28.49

I have checked the harness from the solenoids to the PVC and PVC to ground and they have continuity.

I replaced the angle sensor and it is currently set to 4.4V. I notice that if I move the hydraulics and multifunction for a bit the voltage on the angle sensor kicks down to 1.1V and the machine becomes very slow. If I preform the angle sensor adjustment it automatically goes back to 4.4V without needing to be adjusted and the machine goes back to stalling.

Currently the machine is overloaded. If I move any hydraulic function to fast or to max the machine will stall. I have an MPDr and below are my readings

delivery pressure 4.0-4.3

pump solenoids dn

Ap 23.9

Apr 4.6

DP - 2.6 MPa

when checking the voltage on the solenoids I get these readings

Solenoid #1 with key on engine off

Power (YB) - 24.70

Ground (RBL) - 24.42

Engine running at idle

Power 28.41

Ground 13.44

Solenoid #2 with key on engine off

Power (YB) - 24.45

Ground (Y) - 24.53

Engine running at idle

Power 28.49

Ground 28.49

I have checked the harness from the solenoids to the PVC and PVC to ground and they have continuity.

I replaced the angle sensor and it is currently set to 4.4V. I notice that if I move the hydraulics and multifunction for a bit the voltage on the angle sensor kicks down to 1.1V and the machine becomes very slow. If I preform the angle sensor adjustment it automatically goes back to 4.4V without needing to be adjusted and the machine goes back to stalling.

LACHAU

Senior Member

...

When the new angle sensor is in and set to 4.4V I turn the engine on and the first thing i notice is the engine seems to be under a little load also hydraulics are so fast they stall out the engine, or if I close the bucket and hold it the engine immediately stalls. After a few of these movements the angle sensor kicks down to around 1V and now the hydraulics become very slow. However if I multifunction the speed seems to come back towards normal. I can still idle up fine and there does not appear to be any load on the engine now. Could it be that the new angle sensor is faulty or what would cause it to lose voltage like this? I can unplug the 2 solenoids and the angle sensor goes back to 4.4V with no adjustment needed. I'm still manually getting code 22.

...

I have checked the harness from the solenoids to the PVC and PVC to ground and they have continuity.

I replaced the angle sensor and it is currently set to 4.4V. I notice that if I move the hydraulics and multifunction for a bit the voltage on the angle sensor kicks down to 1.1V and the machine becomes very slow. If I preform the angle sensor adjustment it automatically goes back to 4.4V without needing to be adjusted and the machine goes back to stalling.

- I suggest you to re-check the harness of wires. In addition to the continuity test, you need to check if there is a short circuit.

- At the same time you need to check the connectors for loose, good electrical contact or not?

- How much is the voltage of the high pressure sensor on the pump? Does voltage change follow load pressure?

- regarding to A-sensor, you take it out from main pump==> turn on key==> turn A-sensor by hand==> measure voltage to check whether voltage change follow rotation of A-sensor or not?

Last edited:

RPMex

Well-Known Member

Thank you Lachau I will check these tomorrow and report my findings!

RPMex

Well-Known Member

Hi Lachau,

Today I took the angle sensor off and tested it per your instructions and the voltage does move as you move the shaft so I put it back on and adjusted it to 4.45V

I checked the voltage to the Pressure Sensor it is 5V with key on and when you turn the engine on the output is around 1V touching no controls and when I move the controls the voltage goes up as it starts to stall it spikes up close to 5V

I checked all my harness and looked everything over I can't visually see any breaks in the wires.

Unfortunately I'm not certain how to test for a short circuit for the ground wires on the high pressure solenoids. I should be able to get some info on this and get back to you tomorrow.

Today I took the angle sensor off and tested it per your instructions and the voltage does move as you move the shaft so I put it back on and adjusted it to 4.45V

I checked the voltage to the Pressure Sensor it is 5V with key on and when you turn the engine on the output is around 1V touching no controls and when I move the controls the voltage goes up as it starts to stall it spikes up close to 5V

I checked all my harness and looked everything over I can't visually see any breaks in the wires.

Unfortunately I'm not certain how to test for a short circuit for the ground wires on the high pressure solenoids. I should be able to get some info on this and get back to you tomorrow.

LACHAU

Senior Member

RPMex

Well-Known Member

LACHAU

Senior Member

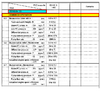

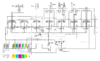

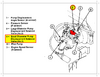

It means the "Pump control system" is currently faulty.I will check these and get back to you shortly. See below the diagnostic results show PVC does just mean that’s what the MPDr is looking at or is that what’s at fault?View attachment 234205 View attachment 234206

Fault code No.22 is usually sensor or wiring problems, but sometimes it's caused by mechanical components !!!

As I wrote here.

Hitachi ex100-3

Hitachi ex100-3

RPMex

Well-Known Member

Copy that I will be checking the sheets you sent over and should have some info for you later today. Thank you so much for the help!!!

RPMex

Well-Known Member

Hi Lachau I was able to get some readings today and they are posted in the two attached pictures. I wasn't able to do any multi-functions as the machines hydraulic oil started over heating before I could get the readings. It was up to 78C

Some of these look good some do not. The Pump Delivery Pressure and Pump Flow rate seem very high as well as most of the Differential Pressure readings. Any function held over relief the pressures spike and machine stalls.

A few things I noticed while running the machine other than the hydraulics getting hot was that the arm roll out was extremely fast and the few short times I had the auto idle on the arm roll in function would not trigger the machine to idle up like all the rest.

I will check the combo function readings tomorrow but I wanted to report what I found and am interested in your thoughts, thank you very much for taking the time to look at these and help your information is extremely informal and I really appreciate it!!!

Some of these look good some do not. The Pump Delivery Pressure and Pump Flow rate seem very high as well as most of the Differential Pressure readings. Any function held over relief the pressures spike and machine stalls.

A few things I noticed while running the machine other than the hydraulics getting hot was that the arm roll out was extremely fast and the few short times I had the auto idle on the arm roll in function would not trigger the machine to idle up like all the rest.

I will check the combo function readings tomorrow but I wanted to report what I found and am interested in your thoughts, thank you very much for taking the time to look at these and help your information is extremely informal and I really appreciate it!!!

Last edited:

LACHAU

Senior Member

According to your information, I think that:

a)- The Differential Pressure sensor (DP-sensor)

b)- The engine speed sensor are faulty.

c)- Main pump of machine can not reduce to minimum displacement in the neutral position!!

So I suggest some actions:

a)- The Differential Pressure sensor (DP-sensor)

b)- The engine speed sensor are faulty.

c)- Main pump of machine can not reduce to minimum displacement in the neutral position!!

So I suggest some actions:

- Check the No. 1 PUMP displacement solenoid valve .... also check the mechanical parts of the main pump regulator (servo piston) for stuck.

- Regarding to the DP sensor, you can make adjustments and at the same time you should carefully check the wiring, connectors.

- Engine speed sensor, you must carefully check the installation, wiring and connectors.

LACHAU

Senior Member

According to your information, I think that:

a)- The Differential Pressure sensor (DP-sensor) is fault.

b)- The engine speed sensor is fault.

c)- Main pump of machine can not reduce to minimum displacement in the neutral position!!

So I suggest some actions:

a)- The Differential Pressure sensor (DP-sensor) is fault.

b)- The engine speed sensor is fault.

c)- Main pump of machine can not reduce to minimum displacement in the neutral position!!

So I suggest some actions:

- Check the No. 1 PUMP displacement solenoid valve....also check the mechanical parts of the main pump regulator (servo piston) for stuck.

- Regarding to the DP sensor, you can make adjustments and at the same time you should carefully check the wiring, connectors.

- Engine speed sensor, you must carefully check the installation, wiring and connectors.

LACHAU

Senior Member

RPMex

Well-Known Member

Great info!!! I will check these today and report my findings. Thank you so much!!!

RPMex

Well-Known Member

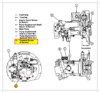

Check the No. 1 PUMP displacement solenoid valve.

From your pictures Solenoid 1 is closest to the entry door and solenoid 2 is closest to the engine. Can you confirm as my manual shows the opposite and the wiring diagram seems too as well.

It’s an EX 100-2 s/n 12L-30145

my manual doesn’t break down the pump at all. These are really great photos I really like the one showing the servo!! Great stuff thank you very much!!!

LACHAU

Senior Member

It's sure.From your pictures Solenoid 1 is closest to the entry door and solenoid 2 is closest to the engine. Can you confirm as my manual shows the opposite and the wiring diagram seems too as well.

It’s an EX 100-2 s/n 12L-30145

Solenoid 1 (ON==>reducing flow, wires color are YB & RL) is closest to the entry door

and solenoid 2 (ON==>increasing flow, wires color are YB & Y) is closest to the engine.

RPMex

Well-Known Member

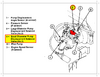

I swapped the solenoid wires over so they are correct and now the MPDr is giving code 22 along with code 29 and 30 for the angle sensor. I checked the harness and am getting 5V and ground is grounded with key on. The sensor was reading an output of 4.4V. I took it back off and when I move the shaft with the key on the voltage goes up and down however it does seem a little sporadic. I put the sensor back in and reset to 4.4V but am still getting the code. Could this sensor be faulty?

I checked the voltage to the dP sensor it is 4.5V with key on and 4.73V with machine running.

I also have to apologize the numbers I put down for engine rpm difference was only the engine rpms.

I checked the voltage to the dP sensor it is 4.5V with key on and 4.73V with machine running.

I also have to apologize the numbers I put down for engine rpm difference was only the engine rpms.

RPMex

Well-Known Member

I'm back with hopefully some good news. I've been delayed because I had to take the starter off and have it rebuilt after giving me fits and not starting. While it was out I replaced all the old sensor connectors on and for the pump. I also replaced the angle sensor with a new one from Hitachi and thankfully now I have no codes. However I do have slow hydraulics especially with the boom up function and walking the machine

Lachau would you mind looking at these numbers again now that I have cleared up the codes. Could it be something in the actual hydraulic system itself? The pump delivery pressure and flow rates seem low.

Lachau would you mind looking at these numbers again now that I have cleared up the codes. Could it be something in the actual hydraulic system itself? The pump delivery pressure and flow rates seem low.

Last edited:

LACHAU

Senior Member

I suggest you look at Angle sensor bolt. It has a Elliptical hole allows you to adjust the position of the sensor, then try to adjust it......

However I do have slow hydraulics especially with the boom up function and walking the machine

Lachau would you mind looking at these numbers again now that I have cleared up the codes. Could it be something in the actual hydraulic system itself? The pump delivery pressure and flow rates seem low.

View attachment 235142View attachment 235143