Nige

Senior Member

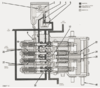

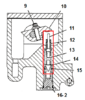

Without a Serial Number it's hard to be specific, attached is the adjustment procedure for a wide variety of D4H II & III machines.

If your S/N is not included post back and I'll see if there is a separate procedure for it.

I assume that you may have already checked but can you see any slop in the linkages anywhere..?

If your S/N is not included post back and I'll see if there is a separate procedure for it.

I assume that you may have already checked but can you see any slop in the linkages anywhere..?