JakeHarrington

Well-Known Member

Hey guys I'm working on my 980h JMS03132

so far I haver had hydraulic, steering, and braking issues since I bought it last winter.

Now I'm on to the transmission issues haha. the machine ran great all day saturday no problem all day. monday warm it up and grease it and go to dig into some piles and first gear has no power.

after a little playing around and getting it warm i learned that 2,3,4 all work properly with full power in both auto shift and manual. when you drop it into first to dig into a hard pile of dirt it drives fine with no load but once you get about a half bucket and start to really push the tranny starts to slip. the tires you can see start to chatter, its not violent just a slight chatter and no power to the wheels, the hydrualics have plenty of power though. after some more test of really ramming the bucket down to backblade the ground i realize first gear reverse has the same problem.

all the dashboard indicators match where ever i have the shift lever.

no codes at all

changed the tranny fluid and cleaned the screen and magnetics and installed a fresh filter on monday morning. oil and filter looked clean, the screen had a few plastic looking flakes but no metal or clutch material , magnets where clean also very clean,

i refilled the tranny with oil and warmed it up, it didn't help at all

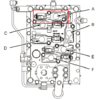

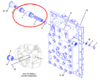

i figured the first gear shift solenoid was acting up so i changed the number 6 shift solenoid because i was told by cat that one does first gear.

new shift soleniod made no difference either.

i ran the machine all day today in just second gear, the machine has plenty of power in 2nd but first is still no good.

I'm waiting on my gauges to come in to test some ports on the tranny, does anyone have any advice what to try next and what i should be looking for when i test the pressures?

thanks you in advance,

Jake Harrington

so far I haver had hydraulic, steering, and braking issues since I bought it last winter.

Now I'm on to the transmission issues haha. the machine ran great all day saturday no problem all day. monday warm it up and grease it and go to dig into some piles and first gear has no power.

after a little playing around and getting it warm i learned that 2,3,4 all work properly with full power in both auto shift and manual. when you drop it into first to dig into a hard pile of dirt it drives fine with no load but once you get about a half bucket and start to really push the tranny starts to slip. the tires you can see start to chatter, its not violent just a slight chatter and no power to the wheels, the hydrualics have plenty of power though. after some more test of really ramming the bucket down to backblade the ground i realize first gear reverse has the same problem.

all the dashboard indicators match where ever i have the shift lever.

no codes at all

changed the tranny fluid and cleaned the screen and magnetics and installed a fresh filter on monday morning. oil and filter looked clean, the screen had a few plastic looking flakes but no metal or clutch material , magnets where clean also very clean,

i refilled the tranny with oil and warmed it up, it didn't help at all

i figured the first gear shift solenoid was acting up so i changed the number 6 shift solenoid because i was told by cat that one does first gear.

new shift soleniod made no difference either.

i ran the machine all day today in just second gear, the machine has plenty of power in 2nd but first is still no good.

I'm waiting on my gauges to come in to test some ports on the tranny, does anyone have any advice what to try next and what i should be looking for when i test the pressures?

thanks you in advance,

Jake Harrington