-

Thank you for visiting HeavyEquipmentForums.com! Our objective is to provide industry professionals a place to gather to exchange questions, answers and ideas. We welcome you to register using the "Register" icon at the top of the page. We'd appreciate any help you can offer in spreading the word of our new site. The more members that join, the bigger resource for all to enjoy. Thank you!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Fuel tank repair

- Thread starter doublewide

- Start date

doublewide

Senior Member

doublewide

Senior Member

doublewide

Senior Member

doublewide

Senior Member

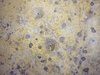

My plan is to lead solder these holes and maybe some of the other deeper pits. Any thoughts on that? What about flamability issues? Should I wash the tank out first? Any input would be appreciated.

I've had very good results with the fiberglass fuel tank repair kits. As clean as you have it it will work very well, perhaps better than soldering and without any risk of combustion. I'm afraid any repair will be a temporary fix, the tank will likely continue to deteriorate to the point of needing replacement.

crane operator

Senior Member

the tank will likely continue to deteriorate to the point of needing replacement.

Steve has the right idea here, but he's got it after messing around with trying to fix it first. Just replace the tank. It won't get better. Replace with a aluminum one. Head for the junkyard, and get the straps for the new tank while you're at it.

Also- no way would I reuse a tank after I'd been after it with a sandblaster. You won't get it all out. It will plug the filters. Hopefully it won't get past the filters. Really really hopefully.

Tenwheeler

Senior Member

Pissin in a strong wind! A good used tank would be best.My plan is to lead solder these holes and maybe some of the other deeper pits. Any thoughts on that? What about flamability issues? Should I wash the tank out first? Any input would be appreciated.

If you have to fix that run a hose in it from a running engine exhaust pipe and cut the bottom out. A bomb requires oxygen. No oxygen no bomb or very little reaction. I accept no responsibility just sharing the idea. Then install new material.

The other side probably will not be far behind. I would remove and pressure wash it out let it dry in the sun. Then there is a product for sealing tanks. One brand name I believe is called Cream. I have bought another from JC Whitney and I am sure there are others. It has to be put in the tank and the tank rotated coating all of the interior. That will be tough in a big tank like that. Follow the directions and let it dry. Have had good results.

Suppose you could do your lead solder and then seal it. The sealer will catch up all your media trash as well.

If those bad spots are at the straps and brackets it will require extra preparation.

Welder Dave

Senior Member

Try to find a good used tank. I had a Hino with a couple pin holes under the strap on top so just used some JB weld. If the bottom is gone probably had a lot of water in it at some point and likely has rust inside. Diesel fuel tanks are much safer to weld than gas tanks but still require safe practices.

highwayghost

Senior Member

I've repaired them before with JB Bond, it worked well and the repair lasted years.

crane operator

Senior Member

The last junkyard aluminum fuel tank I bought was $100. I don't think any fix is going to be less costly than that.

DMiller

Senior Member

With severity of rust just replace or cut out the area and weld in a patch panel lead will not last any better than any other temp patch.

Welder Dave

Senior Member

The problem is it's a gas tank and not a diesel tank so would need to be thoroughly steamed to flush out any gas that got in the pores or pin holes. Aluminum would be a good solution that won't rust out.

John Canfield

Senior Member

I almost blew my young self up when I was repairing a leak on my Volvo 265 station wagon's gas tank (hand me down car.) I thoroughly washed it out or so I thought. I was going to solder or braze the crack and when flame got close there was a huge whoosh and orange flame out the filler neck. After my near death experience and gas tank fix I found out there was a recall on the tank.

doublewide

Senior Member

..... I'm afraid any repair will be a temporary fix, the tank will likely continue to deteriorate to the point of needing replacement.

That's what I'm afraid of. I hate wasting my time.

doublewide

Senior Member

...........no way would I reuse a tank after I'd been after it with a sandblaster. You won't get it all out. It will plug the filters. Hopefully it won't get past the filters. Really really hopefully.

You know, that's what I was thinking when I was blasting it... This sh!t is gettin' every where!

doublewide

Senior Member

Pissin in a strong wind! A good used tank would be best........

You're prolly right.

doublewide

Senior Member

I've repaired them before with JB Bond, it worked well and the repair lasted years.

Done many with fiberglass resin and mat.....

I've done several small tanks with Kreem and had good results, but they were small tanks. Like this one;

https://www.onlycubcadets.net/forum/showthread.php?p=455593#post455593

doublewide

Senior Member

The last junkyard aluminum fuel tank I bought was $100. I don't think any fix is going to be less costly than that.

Definitely not.