Bmk320

Member

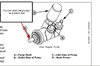

Edit to above. Answered my own question to the check valve. See picture 1

To continue on the diagnostic quest I have encountered a few obstacles as I can not really test the pressure of the transfer pump due to being required to start and run the engine at 2400 rpm nor can I do an accurate bench test of the transfer pump as my pump does not have a hand primer. See below

To continue on the diagnostic quest I have encountered a few obstacles as I can not really test the pressure of the transfer pump due to being required to start and run the engine at 2400 rpm nor can I do an accurate bench test of the transfer pump as my pump does not have a hand primer. See below