-

Thank you for visiting HeavyEquipmentForums.com! Our objective is to provide industry professionals a place to gather to exchange questions, answers and ideas. We welcome you to register using the "Register" icon at the top of the page. We'd appreciate any help you can offer in spreading the word of our new site. The more members that join, the bigger resource for all to enjoy. Thank you!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Hitachi ex 120-3 hydraulic issues

- Thread starter natemarine

- Start date

LACHAU

Senior Member

Of course, the modified job may not work as well as the original. I have actually been doing that since 1999 with EX200-2 excavator.dieseldog, have you ever seen one of those kits actually work? I don't think I have heard of anyone who installed one say it made the machine run like it was supposed to.

dieseldog5.9

Senior Member

I have not seen one on a machine, but considered buying one when I was pulling my hair out with a 120-2/3. I have one customer that has had 5 of these Hitatchi machines and each one has had its issues, in the end got some what proficient with these machines.

I faought with parts that new were junk and that threw me for a loop, DP Sensor from Deere is like 1200 Bucks, overboard if you ask me.

LACHAU, does the 200-2 normally run without electronics or is that something you came up with.

I faought with parts that new were junk and that threw me for a loop, DP Sensor from Deere is like 1200 Bucks, overboard if you ask me.

LACHAU, does the 200-2 normally run without electronics or is that something you came up with.

natemarine

Active Member

I have one question

When field testing the solenoid valves on top of the main pump. I have read and have been told to switch wires to them and see what happens. I'm not sure what's supposed to happen,or what this tells me. Please inform. When I did it, the load came off the hydraulics and the rpms returned to normal. The functions moved very slow. When switched back they machine returned to the same malfunction. Its the first time in a long time I've heard the hydraulics running "stress free"

(weak hydraulics that will stall at full displacement)

Is there a way to test the solenoids with a multimeter?

Still waiting on dr. zx data link cable, trying to use this time produtively

When field testing the solenoid valves on top of the main pump. I have read and have been told to switch wires to them and see what happens. I'm not sure what's supposed to happen,or what this tells me. Please inform. When I did it, the load came off the hydraulics and the rpms returned to normal. The functions moved very slow. When switched back they machine returned to the same malfunction. Its the first time in a long time I've heard the hydraulics running "stress free"

(weak hydraulics that will stall at full displacement)

Is there a way to test the solenoids with a multimeter?

Still waiting on dr. zx data link cable, trying to use this time produtively

mg2361

Senior Member

If you have TM1504, go to section 9025-15. Look for Introduction to Flow Charts and go to the first chart. The first line deals with engine stalls easily under load.

Check to see if you have 24 V to both displacement solenoids with the key on engine off. Each solenoid has it's own relay that supplies them with 24 V.

Yes. Spec is 15.5 (+/-) 5 Ohms

The reason for change when swapping the wires is that one of the wires is supplying the voltage to destroke the pump and the other one is for placing the pump into stroke, so if you put the "destroke" wire onto the "in-stroke" solenoid then when the machine has no levers activated the PVC is sending a signal to destroke (activating the in-stroke valve) and your machine is under load at start up. You need to swap the entire pump displacement solenoid valve assemblies, not the wires to see if one of your displacement solenoids are defective.

Check to see if you have 24 V to both displacement solenoids with the key on engine off. Each solenoid has it's own relay that supplies them with 24 V.

Is there a way to test the solenoids with a multimeter?

Yes. Spec is 15.5 (+/-) 5 Ohms

The reason for change when swapping the wires is that one of the wires is supplying the voltage to destroke the pump and the other one is for placing the pump into stroke, so if you put the "destroke" wire onto the "in-stroke" solenoid then when the machine has no levers activated the PVC is sending a signal to destroke (activating the in-stroke valve) and your machine is under load at start up. You need to swap the entire pump displacement solenoid valve assemblies, not the wires to see if one of your displacement solenoids are defective.

LACHAU

Senior Member

I have not seen one on a machine, but considered buying one when I was pulling my hair out with a 120-2/3. I have one customer that has had 5 of these Hitatchi machines and each one has had its issues, in the end got some what proficient with these machines.

I faought with parts that new were junk and that threw me for a loop, DP Sensor from Deere is like 1200 Bucks, overboard if you ask me.

LACHAU, does the 200-2 normally run without electronics or is that something you came up with.

Last time in Vietnam, we also had a headache with EX DASH 2 electronic parts, so sometimes we had to install the converter as a temporary solution.

The electronic parts of EX-2 are now cheap in Vietnam, so we try to fix it as the original.

If you are going to install the converter for EX-2, it will take you a lot of time for adjustment.

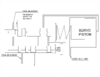

Few pictures of EX200-2 on test bench for your reference.

natemarine

Active Member

Ok guys thank you all for your assistance. I will keep a long story short but here is what the 3 problems I discovered were.

1.angle sensor went bad first a year or so ago

2.(bad solenoid valve) muffler developed a hole and blew hot air on hyd tank and pumps causing additional overheating

during that time one of the solenoid valves on the main pump went bad also

3.(reversed wires) at some point someone I had look at the machine a while back reversed the wires on the two solenoid valves trying to figure out what was wrong when it was the angle sensor

The good thing is now I have the shop manuals and technical manuals and the dr ex diagnostic equipment for when it happens again. Thanks again, machine is sounding great, and lifting heavy weight easily again. Time to get to work!

1.angle sensor went bad first a year or so ago

2.(bad solenoid valve) muffler developed a hole and blew hot air on hyd tank and pumps causing additional overheating

during that time one of the solenoid valves on the main pump went bad also

3.(reversed wires) at some point someone I had look at the machine a while back reversed the wires on the two solenoid valves trying to figure out what was wrong when it was the angle sensor

The good thing is now I have the shop manuals and technical manuals and the dr ex diagnostic equipment for when it happens again. Thanks again, machine is sounding great, and lifting heavy weight easily again. Time to get to work!

mg2361

Senior Member

Good job Nate! Thanks for posting the results. Happy digging .

.

dieseldog5.9

Senior Member

Congratulations, the results sound about par for the course with these Hitachi's. A lot of the time I get calls from people of what is wrong that causes such and such, and alot of the time it is not as cut and dry as change sensor A, I have a proceedure for trouble shooting that works for me, and I have been successfull with however I can't write it down because it is more of a personality than a proceedure, some people would like you to get in and out in an hour, have an answer and machine fixed for $50, thats just not how it works, sometimes diagnostics is verifying systems are good in order to rule them out, like your wiring being reversed, seems simple to verify wiring, and 9 times out of 10 would be correct, but look you caught the 1 out of 10 that needed it. Sounds like you had the diagnosis part handled, we just provided encouragement!

Nige

Senior Member

I've been following this one and like others above it's nice when the person who started the thread actually comes back with the information regarding what the final fix (or fixes) was. Kudos.

natemarine

Active Member

Hi guys hope your all still following. We got back to work yesterday demolition on a pier. I'v noticed two things. The hydraulic power is stronger lifting weight easier and higher than before with no black smoke or load on the engine or stalling. When I hold the controls it functions normally over relief. What I've noticed is a lack of lift power on the boom and stick. Id say it's at about 75% of full power. It used to pull alot harder. I don't dig that often but my guess is it would affect that too.

You all warned me about using after market parts. I'm not sure how I would know if that was the issue, and I'd hate to start buying genuine parts just to find out. I have set the voltage correctly on dp and angle sensors... but I don't know how I would tell.

The aftermarket parts I put on were dp sensor angle sensor pressure sensor and pump control solenoid valves.

I can't find a troubleshoot for weak functioning hydraulics with no stalling etc. I am still trying to install drzx and windr but unsucessful linking the machine so far.

In a strange twist at the end of the day I shut the machine down normally, after shut down for 5 seconds the engine oil pressure alarm started going off..... not while machine was on....only when off

1. How do I tell if the aftermarket parts I used are good or faulty. The voltage checks out so far but I don't know if that's everything.

2. What would cause everything to seem right but just not have the power I should have.

3. What's up with that oil pressure alarm?

4. Machine will still rev up on it's own with no one in cab. As if someone had touched the controls.

thanks guys, it seems like more that 3 problems....still better than it was but not done

You all warned me about using after market parts. I'm not sure how I would know if that was the issue, and I'd hate to start buying genuine parts just to find out. I have set the voltage correctly on dp and angle sensors... but I don't know how I would tell.

The aftermarket parts I put on were dp sensor angle sensor pressure sensor and pump control solenoid valves.

I can't find a troubleshoot for weak functioning hydraulics with no stalling etc. I am still trying to install drzx and windr but unsucessful linking the machine so far.

In a strange twist at the end of the day I shut the machine down normally, after shut down for 5 seconds the engine oil pressure alarm started going off..... not while machine was on....only when off

1. How do I tell if the aftermarket parts I used are good or faulty. The voltage checks out so far but I don't know if that's everything.

2. What would cause everything to seem right but just not have the power I should have.

3. What's up with that oil pressure alarm?

4. Machine will still rev up on it's own with no one in cab. As if someone had touched the controls.

thanks guys, it seems like more that 3 problems....still better than it was but not done

LACHAU

Senior Member

What do you mean???The hydraulic power is stronger lifting weight easier and higher than before with no black smoke or load on the engine or stalling. When I hold the controls it functions normally over relief. What I've noticed is a lack of lift power on the boom and stick. Id say it's at about 75% of full power.

Performance of BOOM and STICK are SLOW or WEAK??

If their performance are weak, you should measure main pump pressure to check.

natemarine

Active Member

just weak, I think theyre moving pretty normal speed

LACHAU

Senior Member

All right, Have you check How is main pump pressure??just weak, I think theyre moving pretty normal speed