Mark Goodman

Member

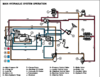

Got a JD 410B backhoe. The hydraulics were a bit slow on it. I changed out the filters and topped off the fluid. Still Slow.

So I decided to Rebuild the pump. Before removing the pump everthing worked; just worked slow. Had plenty of power just wasnt very fast. So I removed the pump and rebuilt it. all new seals and shaft bearings. Once put back on the tractor I now have NO HYDRAULICS. I started it up and backed off all the lines to the pump. I have charge oil coming in from the filter. I have return oil coming in from the trans. I have high pressure going out. I have very little to no charge oil going out.

So I have oil coming into the chargepump but none going out of it. When I took the line off the charge pump that brings oil into the charge pump I have oil. When I take the line off the charge pump that should be taking oil back to the filter I have very little of anything. There is alittle bit of oil but its mostly air that is pumping through. You can hear it pumping or i guess the gears turning is what your hearing, but no oil coiming out. It seems like the gears inside are spining correctly I even took the charge pump back off to make sure there was no binding or broken parts and seen nothing. It seemd just fine to me.

Any help would be great.

Thanks

Mark

So I decided to Rebuild the pump. Before removing the pump everthing worked; just worked slow. Had plenty of power just wasnt very fast. So I removed the pump and rebuilt it. all new seals and shaft bearings. Once put back on the tractor I now have NO HYDRAULICS. I started it up and backed off all the lines to the pump. I have charge oil coming in from the filter. I have return oil coming in from the trans. I have high pressure going out. I have very little to no charge oil going out.

So I have oil coming into the chargepump but none going out of it. When I took the line off the charge pump that brings oil into the charge pump I have oil. When I take the line off the charge pump that should be taking oil back to the filter I have very little of anything. There is alittle bit of oil but its mostly air that is pumping through. You can hear it pumping or i guess the gears turning is what your hearing, but no oil coiming out. It seems like the gears inside are spining correctly I even took the charge pump back off to make sure there was no binding or broken parts and seen nothing. It seemd just fine to me.

Any help would be great.

Thanks

Mark