Tthis is one of those times where not being there can cause hours of work trying to trouble shoot something that might take five minutes if there in person.

First thing I would say is make sure you have this machine blocked so it an not roll and kill you, we don't want to have to explain this to the next owner, if you get my drift!

Now my first question is: When that picture was taken was the air pressure up full and the parking brake button pushed in? That chrome sleeve should be all the way in when parking brake is released. Maybe 1/8 inch exposed at the most. They look to be sticking out close to 2 inches. Why the right one is right against the flange nut

and the left one has a big gap indicates there is a problem in one or both those brake chambers.

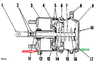

Take a look at this drawing from the information I posted in post #2:

View attachment 207003

When you release the parking brakes air pressure goes into the port with the red arrow pointing to it and moves the piston labeled #4. This piston is attached to that chrome tube you see sticking out. The air pressure pushes the piston up and compresses the spring marked #13 and this releases the brake.

The chamber in the drawing is showing the chamber in the parking brake released mode. As you can tell there is almost none of that chrome tube sticking out the end of the chamber.

The port with the green arrow is where the air goes in to apply the service brakes.

One big word of caution is if you even think about removing and taking one of these chambers apart unless you have worked on them before and fully understand them do not even think about removing the bolts marked #6 in the drawing. That spring marked #13 could be said to have a very appropriate number #13 as it can be very bad luck if it is allowed to be let loose! We don't want the next post here to be from next of kin!

I would be interested in knowing how all the other brake chambers on the machine look in regards of those chrome tubes when machine has full air pressure and the parking brake button is pushed in. They should all be back in like the one in the drawing shows. Again just to be sure you read it before make very sure the machine is blocked so it can not move before getting near it with brakes released. DO NOT trust the bucket to hold it from moving!

This machine has one of the simplest to understand brake systems but also can be a major problem if one does not take the time to understand the basics. If I was located a half hour drive away I would run over and give you a hand this morning, but being on Central NY that's not going to happen!

There are things I might do if there that I would hesitate to even hint at to someone via this forum or by email for fear that what I say might be misunderstood or not followed to the letter.