Hello Stabber.

I'm not in the league of these chaps that are busy solving your problem with your D8,but I'm starting to think that there isn't much wrong with the beast.

Your temp gauges aren't giving me stress.Infact,they look cool to me.

Before you pull the water pump,I'd be buggering about with that water flow sensor.They can lead a man a merry dance if,like me,he's no fitter.

As for the jiggery pokery she gave you the other day after it had been stood a few weeks,remember that she is a big,old girl with a hard life behind her.

Treat it like a woman........Start it up,don't touch it at all,climb off,and leave it idling for 15 minute at least.

Go and have a nice cup of tea or something before even thinking of returning to operate it.

You'll probably find it in a whole different frame of mind,and will find it performs far better.

As for the cooler thing,It costs nowt but time.You must do this task.It will give you an indication of the innards of your cooling system.A good clean up,flush out,and the correct bit of coolant additive and I think you are good to go.

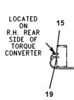

You've done all the heart stopping jobs already with the filters and torque.

I feel you're on the home run,and perhaps your limited experience with the beast has got you on your nerves and abit over cautious.

Nowt wrong with that though.