Jami L Carter

Member

Hello what is the best way to remove pre combustion chambers from a D315 cat engine thank you

Im not familiar with that particular engine. Most Ive seen in the past have an oring seal on the perimeter and a spacer on the threaded shaft. If you are going to reuse your precups, be sure to install the precup in the same hole, with the same spacer, as you removed it. If you replace them, the spacers come in different thicknesses so once the precup is torqued, it is clocked in the right position. If I am wrong on this engine, someone will surely say so.....LOLThank you

Are the precups sealed by threads only.

Im waiting on my book for the D315

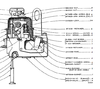

With no S/N to go by it is not easy to answer 100% correct but I'm thinking that the D315 may have the old two piece pre-chambers such as these:

View attachment 192679

If so I believe you need the following tools or figure out how to do the job with something else. I believe where I worked we had those tools and may have used them once in 45 years, maybe on a D399 genset?

View attachment 192680

All I remember are the steel ones (maybe cast).Wow, I thought I was old! I've only seen the one piece pre cup.

I might very well be wrong on the material for the bottom seal. It might have been cast iron? Someone will correct us.

That's better now if SIS had information on that older equipment!Ah my bad s/n 7U16081