Hey guys I have a question about standard flow vs high flow and the heat generation differences of the two.

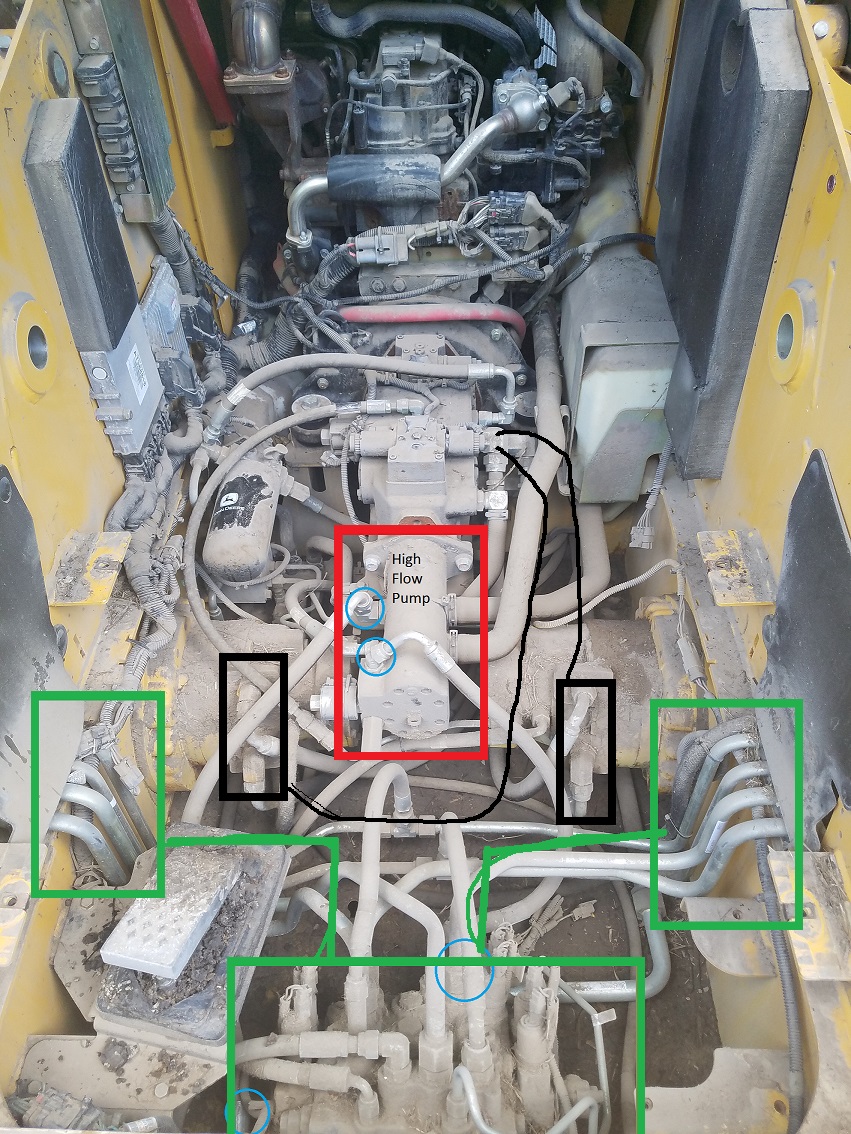

I have a John Deere 332E with high flow at 38GPM that I have been using for excavation, it was a machine I got at a good deal and didnt need high flow but got it anyway. My issue is when running the machine for a few hours of constant digging and doing 180 degree turns (tight spacing), the hydraulic power goes down. Could this be due to the heat generation of a higher flowing pump? I noticed that on the john deere 332e, the oil cooler is the same size regardless if you are high flow or not.

With a standard flow mechine, I am thinking there won't be as much heat generation due to there being less flow and resulting in less of a loss in hydraulic power.

I am trying to see if I can convert my machine back to a standard flow or increase the cooling capacity. Anyone with some advice would be appreciated.

Thanks.

I have a John Deere 332E with high flow at 38GPM that I have been using for excavation, it was a machine I got at a good deal and didnt need high flow but got it anyway. My issue is when running the machine for a few hours of constant digging and doing 180 degree turns (tight spacing), the hydraulic power goes down. Could this be due to the heat generation of a higher flowing pump? I noticed that on the john deere 332e, the oil cooler is the same size regardless if you are high flow or not.

With a standard flow mechine, I am thinking there won't be as much heat generation due to there being less flow and resulting in less of a loss in hydraulic power.

I am trying to see if I can convert my machine back to a standard flow or increase the cooling capacity. Anyone with some advice would be appreciated.

Thanks.