wbvs58

Well-Known Member

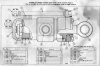

I have to put new seals in the hydraulic cylinder on my D4D. I spoke to the girl at the parts dept of the Cat dealer last week and she was not real helpfull finding the parts I need. The S/N of the machine was of no use to her even though the machine was originally delivered with the Cat ripper on it. She wants a number for the cylinder. I have wiped as much grime from it as I can but can't find any number. I did find two metal tags wrapped around the pipe on it and they have numbers punched into them. One has 2222 on it and the other has what I think is a 6 then a gap to 138-76. Would these numbers mean anything to identify the cylinder? I think maybe the 76 represents 1976 which is around the year I believe the machine was built.

Any help would be appreciated. I don't want to pull down the cylinder until I have the parts to rebuild it.

Ken

Any help would be appreciated. I don't want to pull down the cylinder until I have the parts to rebuild it.

Ken