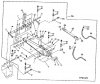

I need to overhaul my JD 110.

Especially the bushing in the dipper is loose.

I can get a new pin, but the factory pin will be too small for the enlargened hole.

I was wondering if anybody has ever reamed out the hole in the dipper, to a uniform size, and then made an oversize pin.

I can machine the oversize pin, but I just don't know if and how they are heat treated.

Does anybody have experience wit that?

Especially the bushing in the dipper is loose.

I can get a new pin, but the factory pin will be too small for the enlargened hole.

I was wondering if anybody has ever reamed out the hole in the dipper, to a uniform size, and then made an oversize pin.

I can machine the oversize pin, but I just don't know if and how they are heat treated.

Does anybody have experience wit that?