d2r

Well-Known Member

Anybody tried refurbing their swing tower with after-market bushings & pins like these... or alternatively, had pins & bushings machined up?

regards... d2r

regards... d2r

"they work well when doing repairs where there is no access to a machine shop, or cust needs to be back to work the next day"

Would it be alright to cut a bigger hole to fit the bushing in with a torch and fill all the gaps with weld?

d2r, Optimum solution is to use the kits, they work well.

"done with my machining and torch hardening"

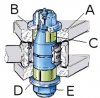

"]Here's another fix, it uses a wedge to expand the bushing to fit the hogged out holes in the casting."

"The last post was July 2010."

The last post was July 2010. Has anyone tried the Expander system yet? If so, would be interested in hearing about it. Thanks, Packratc

"You saw the join date as the post date"

so, probably three grand all in... once it gets installed."We do make parts for your machine, but two of the positions have two available pins with slightly different lengths, so we would need to confirm measurements."

"Also we need to determine the wear in the lugs because each size of sleeve will expand .080” and we can custom fit the sleeves to your requirement. Estimated price for 6 of our assemblies is about $2600."

"Call or email if you have any questions."

Dave Godlove

d2r, I have installed over 40 kits like this on the b,c,d case 580 tractors in the past 20+ years, they work well when doing repairs where there is no access to a machine shop, or cust needs to be back to work the next day, used to keep them on the service truck, lower boom and tower 2.5 hrs, main swing upper/lower 4.5 hrs, when your set up with a good shop or truck and tools it goes together fast.