-

Thank you for visiting HeavyEquipmentForums.com! Our objective is to provide industry professionals a place to gather to exchange questions, answers and ideas. We welcome you to register using the "Register" icon at the top of the page. We'd appreciate any help you can offer in spreading the word of our new site. The more members that join, the bigger resource for all to enjoy. Thank you!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Cat 815F Blade Bearing Failure

- Thread starter Hunter013

- Start date

Nige

Senior Member

They don't have a replaceable bearing.I thought those had a replaceable bearing insert but I can’t tell from the damage. Other than that’s it’s called guaranteed parts sales

They are not lubricated at all because the rotational movement of that joint is only a few degrees. The life of the parts is totally dependent on how well the assembly is kept adjusted (shims #10 under the cap) and when all the shims have been removed the worn parts need to be replaced. I'd say that assembly most probably broke because it was not adjusted correctly over a long period of time.

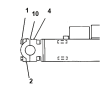

#1 - 2 of each 8T-8925 Bolt & 4F-2710 Nut

#2 - 160-6306 Bearing Cap

#4 - 6J-0800 Bearing which welds into the end of the push arm.

#10 - 8E-5701 Shim (top & bottom as required). They come in packs of 10.

It's hard to see from the photos but you'll probably need a new trunnion ball as well if the existing one is anything like worn. The LH one (they are handed) is a 7V-9591.

The method I always used to determine the correct amount of shims in one of those joints was as follows. Snug the top and bottom bolts up until the Cap pulls the Bearing tight up to the trunnion - but don't heave on them. The Cap #2 does not have to be exactly square to the Bearing #4 but try to get it close. By trial and error see how many shims you can slide into the top and bottom of the joint. Take that total number of shims (top & bottom) and add 2 more. Divide the shims into two equal stacks (they can differ by 1 top & bottom if the original total was an odd number) pull the bolts out one at a time and install the shims. Tighten the hardware to specified torque.

Nige

Senior Member

After looking at your photos a bit more I suspect that wear in the other joints at the blade end were in all probability the major contributors to the failure. There are evident signs of spalling all round the Bearing indicating that the blade end was moving excessively, most likely from side-to-side. So the indications of your failure are effectively telling you to look elsewhere for the root cause. Repair the problem you have now without fixing the rest and you risk having the exact same failure again.

Hunter013

Well-Known Member

the blade end was moving excessively, most likely from side-to-side

The crossbar was not shimmed properly. We welded the new bearing on, shimmed everything. Good as new. Thank you for the help.

Nige

Senior Member

How about some "after" photos to go with the "before" ones.?