Hey thanks for replys

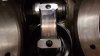

Motor is a Komatsu 6d105. After closer look at motor, the oil pump is at front on motor, but oil filter is on the very back end of motor, it looks like oil galley goes to back end 1st (would that explain 1st bearing fail as least oil getting there?) that copper coloured bearing is at the rear. i will attach pic of broken pump

engine was rebuilt after seizing (we had 15 years of use before seizing) the shop that rebuilt it is a well know one, although we got quoted approx $10,000 (NZD) then they gave us a bill of $24,900, we fought the price down to i believe around $20k. i wouldn't think they done us dodge and put old parts back in after them but who knows. Just looking at repair bill it Had used crank ground and .050 bearings. new oil pump fitted.

no engine start been used. I cut oil filter was just really black but no pieces of debris of any sought. no antifreeze been in oil, hasnt used any fluids since rebuild was running great. (re john c this is all on rebuilt engine, and they charged for new rod bolts)

i have attached new pics of sets of mains and conrod bearing front and back