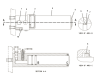

Hello all I am having a problem with my track adjuster not taking grease, pump it up and kicks coupler off. I have replaced the grease fitting with a new one and acts the same. Would like to see an Exploded drawing to better diagnose

Any help would be appreciated. Thanks D.Bird

Serial # CBA01403

Any help would be appreciated. Thanks D.Bird

Serial # CBA01403