I have a Kobelco SK200LC Mark IV Serial# YQU3989. When I put the machine under strain, the hydraulic system will kill the engine. I've had the engine checked out and there doesn't seem to be anything wrong with it. In researching this problem, it seems the hydraulic regulators(compensators?) on the pump should kick in and relieve the pressure in that situation instead of dragging down the engine. If they somehow are adjusted too high, the main relief valve should kick in. At least that's my understanding from my research. I purchased a shop manual that cost a pretty penny and it doesn't show me how to adjust those valves. Is there some documentation that shows a step-by-step procedure for doing so? Thanks in advance for any help.

-

Thank you for visiting HeavyEquipmentForums.com! Our objective is to provide industry professionals a place to gather to exchange questions, answers and ideas. We welcome you to register using the "Register" icon at the top of the page. We'd appreciate any help you can offer in spreading the word of our new site. The more members that join, the bigger resource for all to enjoy. Thank you!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Kobelco SK200LC Mark IV Hydraulic Regulator Adjustment

- Thread starter breauxlg

- Start date

Kobelco ireland

Senior Member

Unless someone adjusted the regulators before, you should never have to adjust them. If engine power is correct then the pump solenoid should stop the hydraulics from overloading the engine. The pump solenoid should destroke the pumps and allow the engine to run at full rpm

I had a diesel guy check the engine and he says it's putting out what it needs to. So if the pump solenoid goes bad, that's how the engine gets overloaded? How do I check that? Also, is there a set of solenoids? The problem is worse on the boom out and in, but it will stop the engine on the bucket dig.

Last edited:

LACHAU

Senior Member

It does not pull down the pressure, but reduces the pump's flow, thereby reducing the load power (which is the pump's power consumption) to match the engine power....In researching this problem, it seems the hydraulic regulators(compensators?) on the pump should kick in and relieve the pressure in that situation instead of dragging down the engine...

That adjustment is done by the regulator. The regulator works by two parts: electrical and mechanical. Even if the electrical part works well but the mechanical part is stuck, the regulator will not be able to adjust the pump power to match the engine power, then the engine will still be overloaded.

I suggest you try to adjust the regulator to see if it still works. Try loosening the 2 screws to see if there is any change?

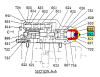

I also have attached a file for your reference about the regulator of SK200LC mark IV machine

Attachments

Last edited:

Tim Modine

Well-Known Member

Breauxlg did you get the issue resolved. I’m having a similar problem with a Doosan solar 225lc-v. Did you have the regulators adjusted?

LACHAU, thanks so much. I'm going to try that just as soon as I can get back to the machine.It does not pull down the pressure, but reduces the pump's flow, thereby reducing the load power (which is the pump's power consumption) to match the engine power.

That adjustment is done by the regulator. The regulator works by two parts: electrical and mechanical. Even if the electrical part works well but the mechanical part is stuck, the regulator will not be able to adjust the pump power to match the engine power, then the engine will still be overloaded.

I suggest you try to adjust the regulator to see if it still works. Try loosening the 2 screws to see if there is any change?

I also have attached a file for your reference about the regulator of SK200LC mark IV machine

View attachment 263400

View attachment 263399

View attachment 263402

I'm going to try that this evening if I can get back to the machine. I'll post the results.Breauxlg did you get the issue resolved. I’m having a similar problem with a Doosan solar 225lc-v. Did you have the regulators adjusted?

Ncjetskier

Well-Known Member

I had the same problem with a Kobelco SK200. The engine ran fine, but the RPMs were too low and it would put a strain on the motor under a heavy load.

Okay, sorry it took so long to get back to you. I tried adjusting the regulators and was able to make the bucket work the way it's supposed to. It doesn't kill the engine, simply loses power. The stick control will still kill the engine, however and trying to use multiple functions - stick, bucket, lift bogs it down severely. I did change the fuel filters, but I was told by my local Kobelco service center to make sure the screen filter going into the injector primer pump is not clogged. That will be my next step since the Kobelco service folks would not be able to get to me for a bit. I'll post results here when I try it. Thanks again for all of your replies and input.LACHAU, thanks so much. I'm going to try that just as soon as I can get back to the machine.

Tim Modine

Well-Known Member

Since my last post, i had my fuel and hydraulic pump pressures checked by a Doosan Tech and everything is in spec. He recommended changing the proportional valve on the hydraulic pump. He believes the proportional valve is not working correctly and sending to much oil to the front pump causing an engine overload situation. So I've got the proportional valve and I am swapping out tomorrow. Ill post results if that cures it next time I'm out with the excavator. Fingers crossed lol.

Phantom970

Well-Known Member

I wish my pump would stall the motor............ my pump is that tired it can’t dig water

does that machine have the “A” mode function? If so, try running on that mode. It makes the pump and motor work together better without so much loading up of the engine.

A= auto

M= manual

B= breaker

They are just work modes

does that machine have the “A” mode function? If so, try running on that mode. It makes the pump and motor work together better without so much loading up of the engine.

A= auto

M= manual

B= breaker

They are just work modes

Okay, was able to adjust most of the functions to get decent functionality, but the adjustment for the left/right travel felt very different from the other three. After breaking the lock nut, it turned very easily by hand. The local Kobelco service guy said if he sent out a mechanic, they would just pull the pump and send it to a local hydraulics shop, so my son-in-law and I pulled the pump and brought it in. The cylinder on that housing was scarred among other problems and their list of parts without the housing was $2,500 and they said the lead time on the housing was 20 weeks. I found a housing that was in stock but was $1,500. So I would have $4,000 in parts plus labor to fix the pump. I ordered a new aftermarket pump with a one year warranty from Conequip for $5,900 delivered. It's coming in Wednesday and I'll let y'all know what happens after we put it back in. The pump did not have any trash in it. We pumped out and drained the hydraulic tank and check all the filters and found no trash, so I guess the scarring happened at some point and they just cleaned up the fluid after that.

ricardo2023

Member

Como te fue??De acuerdo, pude ajustar la mayoría de las funciones para obtener una funcionalidad decente, pero el ajuste para el recorrido izquierdo/derecho se sintió muy diferente de los otros tres. Después de romper la contratuerca, giraba muy fácilmente con la mano. El tipo de servicio local de Kobelco dijo que si enviaba a un mecánico, simplemente sacarían la bomba y la enviarían a un taller de hidráulica local, así que mi yerno y yo sacamos la bomba y la trajimos. El cilindro en esa carcasa tenía cicatrices, entre otros problemas, y su lista de piezas sin la carcasa era de $2500 y dijeron que el tiempo de entrega de la carcasa era de 20 semanas. Encontré una vivienda que estaba en stock pero costaba $1,500. Así que tendría $4,000 en piezas más mano de obra para arreglar la bomba. Pedí una bomba nueva del mercado de accesorios con una garantía de un año de Conequip por $ 5,900 entregada. Llega el miércoles y te dejaré todos saben lo que sucede después de que la volvemos a colocar. La bomba no tenía basura. Bombeamos y drenamos el tanque hidráulico y revisamos todos los filtros y no encontramos basura, así que supongo que la cicatrización ocurrió en algún momento y simplemente limpiaron el líquido después de eso.

ricardo2023

Member

L

De acuerdo, pude ajustar la mayoría de las funciones para obtener una funcionalidad decente, pero el ajuste para el recorrido izquierdo/derecho se sintió muy diferente de los otros tres. Después de romper la contratuerca, giraba muy fácilmente con la mano. El tipo de servicio local de Kobelco dijo que si enviaba a un mecánico, simplemente sacarían la bomba y la enviarían a un taller de hidráulica local, así que mi yerno y yo sacamos la bomba y la trajimos. El cilindro en esa carcasa tenia cicatrices, entre otros problemas, y su lista de piezas sin la carcasa era de $2500 y dijeron que el tiempo de entrega de la carcasa era de 20 semanas. Encontré una vivienda que estaba en stock pero costó $1,500. Así que tiene $4,000 en piezas más de mano de obra para arreglar la bomba. Pedí una bomba nueva del mercado de accesorios con una garantía de un año de Conequip por $ 5,900 entregada. Llega el miércoles y te dejaré todos saben lo que sucede después de que la volvemos a colocar. La bomba no tenia basura. Bombeamos y drenamos el tanque hidráulico y revisamos todos los filtros y no encontramos basura, así que supongo que la cicatrización ocurrió en algún momento y simplemente limpiaron el líquido después de

resuelto?