-

Thank you for visiting HeavyEquipmentForums.com! Our objective is to provide industry professionals a place to gather to exchange questions, answers and ideas. We welcome you to register using the "Register" icon at the top of the page. We'd appreciate any help you can offer in spreading the word of our new site. The more members that join, the bigger resource for all to enjoy. Thank you!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

3406B Running hot?

- Thread starter Keith Merrell

- Start date

Truck Shop

Senior Member

Keith Merrell

Well-Known Member

Thank you!

Keith Merrell

Well-Known Member

I condemned the fan clutch too quickly. Replaced with a new OEM viscous clutch. No difference in temperature. What next? Thermostat, water pump? Pressure test radiator? New core? When I hit the top of the grade in Sedona I was running 210 with no sound of the fan coming on. I have a 6 blade fan currently. Should I replace with an 8 or 9 blade? Was going 40mph towing 22k on the tag trailer running 1750 rpm about 850-900 EGT I recall.

Coaldust

Senior Member

- Joined

- May 9, 2011

- Messages

- 3,346

- Location

- North of the 60

- Occupation

- Cargo Tanks, ULSD, RUG, Methanol, LPG

I was watching and was afraid the fan wouldn’t fix the problem. Those engines eat water pumps. So many PSP, PIP campaigns, Service Magazine & Truck Engine News bulletins about those. Many product updates. It could still have original fiber impeller that is known for slipping. You could take some temps, run some numbers, check some delta T’s or just change the water pump, backing plate & T-stats. New coolant. The problem will probably go away.

I just changed a water pump on a 3406B with a fiber impeller. That was overheating. Whoduthunk there would still be fiber impeller water pumps left in the wild?

I just changed a water pump on a 3406B with a fiber impeller. That was overheating. Whoduthunk there would still be fiber impeller water pumps left in the wild?

Truck Shop

Senior Member

At 1750 your near the bottom of torque range. EGT's will climb.

skyking1

Senior Member

roll it back to about 1600, TS? Even lower?

Enquiring 3406B operators want to know

Enquiring 3406B operators want to know

Last edited:

Truck Shop

Senior Member

roll it back to about 1600, TS? Even lower?

Enquiring 3406B operators want to know

Drive it how ever you want to, I'm not repairing it or paying the bill.

Coaldust

Senior Member

- Joined

- May 9, 2011

- Messages

- 3,346

- Location

- North of the 60

- Occupation

- Cargo Tanks, ULSD, RUG, Methanol, LPG

skyking1

Senior Member

This truck doesn't have a pyro or anything so I was just looking for clues. I only have a few grades I pull, none long enough to figure out The best practices.Drive it how ever you want to, I'm not repairing it or paying the bill.

Truck Shop

Senior Member

Old rule of thumb, If your hard on the throttle to maintain speed on a grade or can't gain speed you need

to drop one gear. Should maintain speed easily at 65% throttle. If it's a 2100 rpm engine it should be pulling

easy at 1900 and running 195* to 200* with fan engaged.

to drop one gear. Should maintain speed easily at 65% throttle. If it's a 2100 rpm engine it should be pulling

easy at 1900 and running 195* to 200* with fan engaged.

Truck Shop

Senior Member

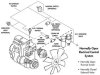

Jack Crews said “Ain’t Nothing Like a Caterpillar Engine”. I believe him. View attachment 259926

Yeah, uh ha jack crews.

This truck doesn't have a pyro or anything so I was just looking for clues. I only have a few grades I pull, none long enough to figure out The best practices.

Yea i'm in the same boat. I tend to drop a gear if it hits 1400, and keep it at 1500-1700 for hard pulls. But no long grades here either. I haven't found a grade mine won't hold speed at in 7th even at 90,000lbs.

Tenwheeler

Senior Member

You can check that pretty easy without swapping parts. Plumb a pressure gauge into the side of the block. Should run around 30 psi steady at speed. Best to be able to watch it while driving. Slipping on shaft can come and go with different temperatures.Hi after you have checked all of the above.check to see if the water pump impeller is not turning on the shaft.the impeller is a taper fit on the shaft and if not fitted correctly can come loose.

Also there were a batch of water pumps that had a plastic type impeller bonded to a steel hub, when hot the impeller would spin on the hub

Mark

skyking1

Senior Member

Thanks, that is how I drive. if it won't accelerate then back out of that one and go a hole lower. This truck runs 175 and I might get to 190 on my little pulls. It has the air fan.Old rule of thumb, If your hard on the throttle to maintain speed on a grade or can't gain speed you need

to drop one gear. Should maintain speed easily at 65% throttle. If it's a 2100 rpm engine it should be pulling

easy at 1900 and running 195* to 200* with fan engaged.

I figure with 325 hp and 1075 torque it is pretty modest fueling, so not too likely that it will cook too hot to need a pyro.

Keith Merrell

Well-Known Member

You can check that pretty easy without swapping parts. Plumb a pressure gauge into the side of the block. Should run around 30 psi steady at speed. Best to be able to watch it while driving. Slipping on shaft can come and go with different temperatures.

Keith Merrell

Well-Known Member

Clock spring

Mark the little shaft in the center of the spring and heat it with a heat gun to see where it goes when it gets hot and stretch the spring to make it stay in that position when cool .I have had good luck with this,maybe it wil work for you