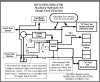

My grapple came with a two spool solenoid valve. My excavator had a hammer circuit activated by a button on one of the joysticks. I plumbed the solenoid valve using the hammer circuit as a feed. The pressure side of the hammer circuit went into the pump port on the new valve, the return line to the tank port. When the solenoid valve is a rest, the oil from the hammer circuit simply flows through the valve and back to the tank. I then connected the hoses that go to the arm to the work ports on the solenoid valve. I wired the auxiliary control switches to the solenoids on the new valve, and to activate the hammer circuit when any function is activated. This way the hammer circuit flow is only activated when one of the functions on the new valve is called for.

This gave me two full double acting circuits to the end of the arm. The only downside is the control switches are on/off type, not variable, so I can't feather the functions. I need to look into variable switches and figure out if they will work with these solenoids.

Hope that makes sense.