Egan

Member

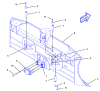

While replacing a track tension seal, I decided to repair the ram that angles the blade (in and out) on our 2006 D4G. I did not realized how much trouble that was going to be before I decided to do this. Ended up making a press out of a 20 ton bottle jack. Now I have the question, Which way do I Press out the pin? Do I push it up or down?