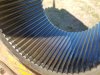

Well I have seen some Midland Bankers in my days, but these boys take the Gold Cup I feel, lucky that no injury resulted I know they managed to pull the rim but they must have damaged something doing this , the tooling they used was totally the wrong kit, pressing the rim back on might be an interesting thing to view, the correct adapter used to dismount and install the rim would have limited the travel of the rim when pulled to 10 mm, there is always the comment that we used what we had, or that's all we had to do it with, well all they were doing was damaging the equipment, they need to learn their Trade or keep clear of this sort of work, even them little Toffee Hammers they tapped on the rim with made my chin drop, when I give a rim a whack it's with a good bit of force, well worth watching thank you .RC. for posting this Comedy.