Terexcat

Member

Hi All

New to this (today) so, Rookie.... (and a very frustrated contractor)

Anyway here's my problem - 2007 Cat D6N LGP, Bought a brand new complete undercarriage from Finning Cat here in Canada, to the tune of $46,000. Got it in the field, and 6 mins after working it, shut it down. The tech said they set Track tension at Cat and tested in yard, but as soon as I got pushing dirt on a slope, she wanted to start jumping on the sprockets.

So i shut down and tightened them a bit, but not too tight. Stopped jumping, but the whole time I ran it, it would work fine going straight forward, but in a slight turn left or right, there was a constant clunk, clunk, clunk - which was-

at about 11 oclock each revolution, the rails would crawl/hang up on the sprocket segments, and then flop back down at about 1 oclock. And both the rails and sprocket segments are scuffing- So obviously wearing out prematurely.

(Keep in mind this is Brand New- everything)

Cat sent someone out, and his comment was, "We want to look after this for you" - That was over a month ago.

His other comment was-

" Hmmm- looks like the rails aren't running true in relation to the sprockets' - as in they were somehow crooked and not engaging the sprockets right. I made the mistake of agreeing with him, but to me it looks like there is too much space between the width of the sprocket and the width of the insides of the rails, creating 'slop'.

So it's not the sprockets (that are immovable) but the rails, that to me, are 'sloppy' when engaging the sprocket segments.

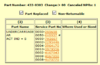

He assured me the part #'s were checked, and the parts are all correct for this machine.

If the bearings on the drive assembly were shot that bad, there would be oil gushing out everywhere, so i don't buy the comment.

Cat wants me to haul it in, on my own dime, ($1000, then haul it back out to my unfinished job again- another $1000 ) saying we need to bring it in to diagnose it.

I haven't ran it all winter, we're shut down- and I don't want to run it till it's rectified - the rails and sprockets will wear out twice as fast as they should

My question is- Is there anyone out there having similar problems with Brand New Undercarriage from Cat?? Is there possibly a hidden recall on some parts??

Please help -

Thanks

Curtis

New to this (today) so, Rookie.... (and a very frustrated contractor)

Anyway here's my problem - 2007 Cat D6N LGP, Bought a brand new complete undercarriage from Finning Cat here in Canada, to the tune of $46,000. Got it in the field, and 6 mins after working it, shut it down. The tech said they set Track tension at Cat and tested in yard, but as soon as I got pushing dirt on a slope, she wanted to start jumping on the sprockets.

So i shut down and tightened them a bit, but not too tight. Stopped jumping, but the whole time I ran it, it would work fine going straight forward, but in a slight turn left or right, there was a constant clunk, clunk, clunk - which was-

at about 11 oclock each revolution, the rails would crawl/hang up on the sprocket segments, and then flop back down at about 1 oclock. And both the rails and sprocket segments are scuffing- So obviously wearing out prematurely.

(Keep in mind this is Brand New- everything)

Cat sent someone out, and his comment was, "We want to look after this for you" - That was over a month ago.

His other comment was-

" Hmmm- looks like the rails aren't running true in relation to the sprockets' - as in they were somehow crooked and not engaging the sprockets right. I made the mistake of agreeing with him, but to me it looks like there is too much space between the width of the sprocket and the width of the insides of the rails, creating 'slop'.

So it's not the sprockets (that are immovable) but the rails, that to me, are 'sloppy' when engaging the sprocket segments.

He assured me the part #'s were checked, and the parts are all correct for this machine.

If the bearings on the drive assembly were shot that bad, there would be oil gushing out everywhere, so i don't buy the comment.

Cat wants me to haul it in, on my own dime, ($1000, then haul it back out to my unfinished job again- another $1000 ) saying we need to bring it in to diagnose it.

I haven't ran it all winter, we're shut down- and I don't want to run it till it's rectified - the rails and sprockets will wear out twice as fast as they should

My question is- Is there anyone out there having similar problems with Brand New Undercarriage from Cat?? Is there possibly a hidden recall on some parts??

Please help -

Thanks

Curtis