MarineHEmech

Member

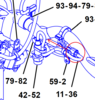

I'm new here but i have high hopes. I really need help. I'm a Marine Corps HE mechanic and I'm working on this Cat 120M motorgrader that keeps this code 127-3 saying the transmission oil pressure sensor voltage is about normal. My problem is that i have no idea where it is located on the trans and how to test it. None of my technical manuals have any information on this code at all and it's had me stumped for the past week. This gear is leaving to go on a deployment really soon and i need it serviceable ASAP. The serial number is NJD 00136. Thanks in advance for any information.