Nige

Senior Member

While you are messing with the A1 & A2 solenoids do you have an external power source you can hook up to each of them in turn with the engine running to see if they work and the hydraulics load up.? Even better if you have an attachment that can be connected hydraulically to the machine.

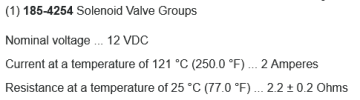

The only problem I have right now is I can't find information regarding the operating voltage of the solenoids, so to be safe I wouldn't recommend applying any more than 6v to them, certainly not battery voltage.

The only problem I have right now is I can't find information regarding the operating voltage of the solenoids, so to be safe I wouldn't recommend applying any more than 6v to them, certainly not battery voltage.