Here is the situation I am running into.

2010 D6T, 8,700 hours. I am pushing sand and lots of it.

all fluid levels ok.

I bought the machine used and it came out from a fly ash operation.

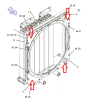

I have cleaned/lightly power washed the radiator multiple times and have removed a lot of fly ash chunks that were in between the radiator fins.

the machine runs great for about two hours. Temp levels stay consistent. Then, after about 2.5 hours the machine temps get to the large tick on the gauges and then goes above them. If I’m pushing and running the machine they just keep going up. Temps are never in the red, but they also can’t bring themselves down unless I idle the machine for 15 minutes. I can run for about 20 minutes and up they go again.

could this be due to more blockages from the ash or something else?

thanks

2010 D6T, 8,700 hours. I am pushing sand and lots of it.

all fluid levels ok.

I bought the machine used and it came out from a fly ash operation.

I have cleaned/lightly power washed the radiator multiple times and have removed a lot of fly ash chunks that were in between the radiator fins.

the machine runs great for about two hours. Temp levels stay consistent. Then, after about 2.5 hours the machine temps get to the large tick on the gauges and then goes above them. If I’m pushing and running the machine they just keep going up. Temps are never in the red, but they also can’t bring themselves down unless I idle the machine for 15 minutes. I can run for about 20 minutes and up they go again.

could this be due to more blockages from the ash or something else?

thanks