I finally decided to move ahead with putting a SS quick attach on my excavator, & do it to use my existing Klac quick coupler. I am in the midst of the process now, & I will chronicle the entire process here for everyone's information &, hopefully, enjoyment.

Step 1, die grind out the lift holes on my Klac quick coupler to enlarge them slightly to about 1.95" dia. This allows the holes to accept a 1.9375" dia. pin, that will be made from surplus polished steel rod (hydraulic rod??) that I picked up cheap. Here is a photo of the coupler just after I finished enlarging the holes:

Step 2

Step 2, buy a Klac blank, or attach plate, that will be welded to my attachment hangers & that will mate to my quick coupler. This req'd about 3 weeks to get from Werk-Brau. Here it is just after I picked it up from my dealer, Andersen Equipment:

Step 3

Step 3, buy a SS quick attach blank from Thor Attachments (John Gustafson) in Wisconsin. That req'q about a month for John to fabricate & have UPS-delivered to me. As I expected from previous experience with a similar quick attach that I had bought from John for my tractor FEL, the new one from John is a "thing of beauty"!! Here it is just after it arrived:

In the above photo, the top rail looks a little bent/curved, but it is NOT...it's just a photographic effect. Some other things to note about this item:

- It's actually called a Multi-Hitch, because it includes 3 - 2" receiver tubes in the lower rail. This feature is unique to John's product I believe, & is a stoke of genius that has a myriad of uses. It's one of the main reasons I endorse John's quick attach over others, never mind the overall build quality! I have the same tubes on my tractor's quick attach, & I can't tell you how handy they are.

- It's built a little heavier than the model for a tractor, to withstand the added stresses that an excavator will impose.

- John actually offers these same blanks with hangers built to match your excavator. But he's never built one for use with a Klac quick coupler, & his complete units cost a lot more $$, he says to cover his liability when you use one on an excavator. I think you are better off building your own hangers, not only to save $$, but so you can custom design/build the hangers to fit your own machine & the way you intend to use your attachment. You will see this in the next step.

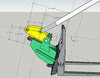

Step 4, design custom hangers between the Multi-Hitch & my Klac coupler. This was the most time consuming part, involving me building a 3D model of my setup in SketchUp, building a representation of the Multi-Hitch & my pallet forks out of scrap wood, & building several test hangers out of scrap wood to test & verify my design. It was basically an iterative process, alternating between software & building, in order to find my "sweet spot" configuration. (Continued in next post.)