JakeHarrington

Well-Known Member

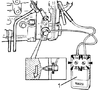

i have to send out my injection pump for some work.

I know i need to put the motor and pump back in time when installing the pump.

Also know that im supposed to have this position indicator timing light position tool from volvo to do this aswell. I dont have this tool and im not spending 780 bucks to buy it for one time use either.

Does anyone have any advice on installing this pump? I havent removed it from the machine yet and i dont plan on removing it until im sure i can reinstall it.

As of right now my only option is having my local dealer taking the service truck out and charging me $175 for 3-6hrs just to put the pump in time. And that sounds alittle unreasonable if you ask me.

Any tips and tricks would be greatly appreciated. Thanks

I know i need to put the motor and pump back in time when installing the pump.

Also know that im supposed to have this position indicator timing light position tool from volvo to do this aswell. I dont have this tool and im not spending 780 bucks to buy it for one time use either.

Does anyone have any advice on installing this pump? I havent removed it from the machine yet and i dont plan on removing it until im sure i can reinstall it.

As of right now my only option is having my local dealer taking the service truck out and charging me $175 for 3-6hrs just to put the pump in time. And that sounds alittle unreasonable if you ask me.

Any tips and tricks would be greatly appreciated. Thanks