I have a 1997 924 f with a 6YX05446 transmission, that I can't get to go into gear. I am the 4th or 5th person to work on this machine, and was told that one of the people that worked on it, hot wired and got it to move to it's current spot. I have been working on the assumption that it was an electrical problem, and finally found the hot wire for the ecm hooked to the fuse for the lights on the machine, which was blown. Still the only power that I have going into the shifter is for the backup alarm, which works if the key is on or not. I decided to see what the psi was on the transmission valve body, so I pulled the p1 fitting out, and had no fluid at all coming out, I then pulled the p3 fitting out and also had no fluid coming out. I have no manual for this machine but have found a few things on line that has helped me get to the point that I am at now, but I can't seem to find anything on if there is a bypass solenoid or some other reason that I am getting no fluid thru the valve body, or is the torque converter or pump out. I do have fluid traveling to the filter, although I didn't put a gauge to it, just broke the line loose to see if I had flow. Any advice on where to look would be appreciated. Mike

-

Thank you for visiting HeavyEquipmentForums.com! Our objective is to provide industry professionals a place to gather to exchange questions, answers and ideas. We welcome you to register using the "Register" icon at the top of the page. We'd appreciate any help you can offer in spreading the word of our new site. The more members that join, the bigger resource for all to enjoy. Thank you!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Cat 924f transmission problems

- Thread starter Mikemg61

- Start date

Mark250

Senior Member

- Joined

- Aug 30, 2015

- Messages

- 1,243

- Location

- victoria,Australia

- Occupation

- heavy equipment technician

hi ,from the transmission S/N the machine S/N is 5NNxxxxx

some questions

have you checked the basics ?

oil level

obvious noises ,vibration etc ?

transmission screens and filters for debris and contamination

previous history ie failed after service or repair work

Is the machine standard or auto shift ?

have you checked the neutralizer is not active ? iAre the brake pedals sticking down?

Have you checked the fuses for the transmission control?

Mark

some questions

have you checked the basics ?

oil level

obvious noises ,vibration etc ?

transmission screens and filters for debris and contamination

previous history ie failed after service or repair work

Is the machine standard or auto shift ?

have you checked the neutralizer is not active ? iAre the brake pedals sticking down?

Have you checked the fuses for the transmission control?

Mark

I have checked to see if there is oil in it, they have lost the dipstick and have a rag stuffed in it. The owner assure me that he put Cat brand oil and filter in it when he worked on it last. There are noises that it makes but not sure if it's the hydraulics or trans. I don't have a manual on this machine, and haven't been able to find a breakdown of the system to know where screens are located. it is auto shift. The neutralizer has been replaced and is not inside the brake pedal assy. The fuses are a mess, the hot wire for the ecm is on the fuse for the lights. It is suppose to have a hot wire to the shifter on pin #1 and ground on #2. I have the ground but no hot, except for the back up alarm. The filter was new when they last changed the oil on the machine, and looks fine. I just started looking at the machine for a friend, and I am the 4th or 5th one in, and have stepped into a mess. Lot's of wires stripped back and not taped back up every where. He did tell me that they put a new ecm and shifter in it, but didn't help. He was using it and it just quit working, didn't say anything about it slipping or not, just was using it, put it in reverse, and wouldn't work again.

Mark250

Senior Member

- Joined

- Aug 30, 2015

- Messages

- 1,243

- Location

- victoria,Australia

- Occupation

- heavy equipment technician

sounds like to me you should walk away from this one ,but if you cant for some reason I will try and help. but you will need to obtain some basic test gear

hydraulic gauges and multimeter

Mark

hydraulic gauges and multimeter

Mark

laycobeau

Well-Known Member

- Joined

- Jul 8, 2013

- Messages

- 219

- Location

- Tulsa Ok. beau.bowlan@lei-corp.com

- Occupation

- Lead electronic technician

The hot to pin 1 comes from the transmission control fuse should be hot with key on

with out power you get no shift signal to the solenoids to shift. Broken wire or

bad fuse. Is the transmission control a Funk or a Clark/Dana/Spicer.

beau.bowlan@lei-corp.com

with out power you get no shift signal to the solenoids to shift. Broken wire or

bad fuse. Is the transmission control a Funk or a Clark/Dana/Spicer.

beau.bowlan@lei-corp.com

laycobeau

Well-Known Member

- Joined

- Jul 8, 2013

- Messages

- 219

- Location

- Tulsa Ok. beau.bowlan@lei-corp.com

- Occupation

- Lead electronic technician

You can view this but I think you have to pay to download.

https://www.scribd.com/doc/17005999...-Loader-Electrical-and-Hydraulic-Systems-pdf#

Did you find out why pin 1 is not hot?

https://www.scribd.com/doc/17005999...-Loader-Electrical-and-Hydraulic-Systems-pdf#

Did you find out why pin 1 is not hot?

Mark250

Senior Member

- Joined

- Aug 30, 2015

- Messages

- 1,243

- Location

- victoria,Australia

- Occupation

- heavy equipment technician

hi ,if you are going ahead and try and sort it out your self, let me know

you will need a 0 to 500psi pressure gauge ,2 if possible a digital multimeter a good led test light

because it has been butchered we need to start at the basics

check for diagnostic codes at the fault light behind the right hand platform ladder

check the transmission shifter fuse and the auto shift fuse

check the auto shift switch is in manual

operate the neutralizer over ride is working ,the light in the dash should come on

remove the transmission filter and cut open and check for contamination

remove the transmission screen in the bottom of the transmission and check the magnet and screen for contamination

if everything is ok so far, connect a 500psi gauge to the P1 and P2 test ports and record the pressure .they should be 350 psi for P1 and 310psi for P2

select first gear forward and use something metallic usually a screwdriver is ok and see if there is a magnetic attraction at the engaged transmission solenoids for first gear they will be solenoids 3 and 4

if no attraction use your multimeter to check for 24 VDC at the solenoid connections

let me know how you go so we can see what's going on

if you PM me your email I may be able to send you some info

Mark

you will need a 0 to 500psi pressure gauge ,2 if possible a digital multimeter a good led test light

because it has been butchered we need to start at the basics

check for diagnostic codes at the fault light behind the right hand platform ladder

check the transmission shifter fuse and the auto shift fuse

check the auto shift switch is in manual

operate the neutralizer over ride is working ,the light in the dash should come on

remove the transmission filter and cut open and check for contamination

remove the transmission screen in the bottom of the transmission and check the magnet and screen for contamination

if everything is ok so far, connect a 500psi gauge to the P1 and P2 test ports and record the pressure .they should be 350 psi for P1 and 310psi for P2

select first gear forward and use something metallic usually a screwdriver is ok and see if there is a magnetic attraction at the engaged transmission solenoids for first gear they will be solenoids 3 and 4

if no attraction use your multimeter to check for 24 VDC at the solenoid connections

let me know how you go so we can see what's going on

if you PM me your email I may be able to send you some info

Mark

Thanks Mark. My email is mikemg61@aol.com. Ok the fault light is not working, I can use my power probe and give it ground and it will light up, but not able to get any flash codes off of it. I still have not found a power source, on either plug for the #1 pin, I have ground on #2 but the #1 wire is #720 which best I can tell is the neutralizer wire, but is not hot and if I put power to it with my power probe still does nothing. I have gotten power to the white wire, #164 for power to the ecm, that is behind the seat. And also have power to #126 pink, for the xmsn shifter on one diagram that I have, I have one wire that I haven't found yet that on my diagram is #120 yellow, for the converter. This is a side job that I am working on for a friend, so I only get to work on it when I'm not working OT, which isn't very often this time of year. I need to check the neutralizer wire with the switch closed to see if power is present with it closed. The neutralizer over ride does have a light that comes on in the dash. The filter and oil he just replaced a couple of weeks ago, when I told him that I would look at it when I got the chance, and said that they cleaned the screens also, but said it was already pretty clean. I have no pressure at all on P1, or P3, haven't checked P2, I didn't have the right fitting to hook up to it, so I just pulled the fittings with it running and had no fluid flow at all. I have the fitting that I need now, but I hooked to gauges up to the fittings on the filter housing to check if the pump was working at all and had around 60lbs on 1, and around 80 on the other at idle, and 140-160 at full throttle, so it is pumping oil through the system. I'm wondering if the wire for the converter is causing the fluid not to get to the valve body?hi ,if you are going ahead and try and sort it out your self, let me know

you will need a 0 to 500psi pressure gauge ,2 if possible a digital multimeter a good led test light

because it has been butchered we need to start at the basics

check for diagnostic codes at the fault light behind the right hand platform ladder

check the transmission shifter fuse and the auto shift fuse

check the auto shift switch is in manual

operate the neutralizer over ride is working ,the light in the dash should come on

remove the transmission filter and cut open and check for contamination

remove the transmission screen in the bottom of the transmission and check the magnet and screen for contamination

if everything is ok so far, connect a 500psi gauge to the P1 and P2 test ports and record the pressure .they should be 350 psi for P1 and 310psi for P2

select first gear forward and use something metallic usually a screwdriver is ok and see if there is a magnetic attraction at the engaged transmission solenoids for first gear they will be solenoids 3 and 4

if no attraction use your multimeter to check for 24 VDC at the solenoid connections

let me know how you go so we can see what's going on

if you PM me your email I may be able to send you some info

Mark

No not having any luck on it, the wire on pin 1 is #720 which on the diagram that I have is the neutralizer wire, but I can put power to it and it doesn't do anything.You can view this but I think you have to pay to download.

https://www.scribd.com/doc/17005999...-Loader-Electrical-and-Hydraulic-Systems-pdf#

Did you find out why pin 1 is not hot?

laycobeau

Well-Known Member

- Joined

- Jul 8, 2013

- Messages

- 219

- Location

- Tulsa Ok. beau.bowlan@lei-corp.com

- Occupation

- Lead electronic technician

Sorry we are on different connectors I was looking at the 40 pin on the controller

Pink #126 is your hot wire looks like #720 is a ground to enable and it is the

neutralizer. I think you are going to need some help on this from a trained person.

Pink #126 is your hot wire looks like #720 is a ground to enable and it is the

neutralizer. I think you are going to need some help on this from a trained person.

Mark250

Senior Member

- Joined

- Aug 30, 2015

- Messages

- 1,243

- Location

- victoria,Australia

- Occupation

- heavy equipment technician

don't be concerned with this wire it has nothing to do with your problemI'm wondering if the wire for the converter is causing the fluid not to get to the valve body?

the convertor you are talking about is 24v to 12 v voltage reducer for radios etc.

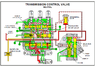

here is a copy of the electrical schematic

Attachments

Last edited:

don't be concerned with this wire it has nothing to do with your problem

the convertor you are talking about is 24v to 12 v voltage reducer for radios etc.

here is a copy of the electrical schematic

Mark250

Senior Member

- Joined

- Aug 30, 2015

- Messages

- 1,243

- Location

- victoria,Australia

- Occupation

- heavy equipment technician

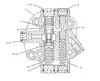

hi ,before you get involved too deep with the electrical side of things, it is more important to understand why the pressures are so low .could you please do a proper pressure check of P1,P2, P3 convertor out also the lube pressure if you don't know where the test points are let me know

some possible causes of low pressure

worn out transmission pump

air leaks on suction side of pump

flow control valve stuck

modulating relief valve stuck

blocked orifices in modulating relief valve

dump valve stuck

I will send you some info on the control valve and the flow control valve

Mark

some possible causes of low pressure

worn out transmission pump

air leaks on suction side of pump

flow control valve stuck

modulating relief valve stuck

blocked orifices in modulating relief valve

dump valve stuck

I will send you some info on the control valve and the flow control valve

Mark

Mark250

Senior Member

- Joined

- Aug 30, 2015

- Messages

- 1,243

- Location

- victoria,Australia

- Occupation

- heavy equipment technician

I did pressures on the p1, p2, p3. Came up with 0 pressure on those three. I pulled the gauge off and did have a very little amount of flow but not enough to register on the gauge. The only other pressure that I got was at the filter, there are 2 ports there, got 60lbs on one, and 80lbs on the other. I looked all around the bell housing and didn't see any pressure point for the converter, and I don't have the adapter plate for the other pressure reading. I'm not sure exactly where the modulating relief valve or dump valve are located, but I'm assuming that it's under one of the Allen head plugs.

Mark250

Senior Member

- Joined

- Aug 30, 2015

- Messages

- 1,243

- Location

- victoria,Australia

- Occupation

- heavy equipment technician

hi , I sent the disassembly and assembly instructions for the valve to your email

mark

mark

Mark250

Senior Member

- Joined

- Aug 30, 2015

- Messages

- 1,243

- Location

- victoria,Australia

- Occupation

- heavy equipment technician