SubMech

Member

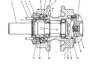

Looking for some tips on how to best disassemble a top roller off my 215B (9YB03340). It is off the machine on the bench.

For example, do I press the shaft out of the hub from the cover side or press the shaft out of the mount bracket?

Seal housing seems to have dowels and a snap ring holding it to the mount.

For example, do I press the shaft out of the hub from the cover side or press the shaft out of the mount bracket?

Seal housing seems to have dowels and a snap ring holding it to the mount.