LukeWilson

Member

Hi everyone, I've been lurking around the forum for some time now but am hoping you guys can help me with my latest problem.

I recently purchased a 1969 580CK diesel with a power shuttle and 4 speed. I bought this machine not running with a broken ring gear on the flywheel. Over the course of a few weekends, I managed to split the tractor and replace the ring gear successfully. This is my first piece of heavy equipment so I learned a lot along the way.

Once the tractor was running I went through the machine and replaced all the fluids and filters, put a couple new tires on the rear, installed new gauges, re-wired the tractor and welded on a roll bar. Everything seemed to be working well with the exception of a couple leaky cylinders.

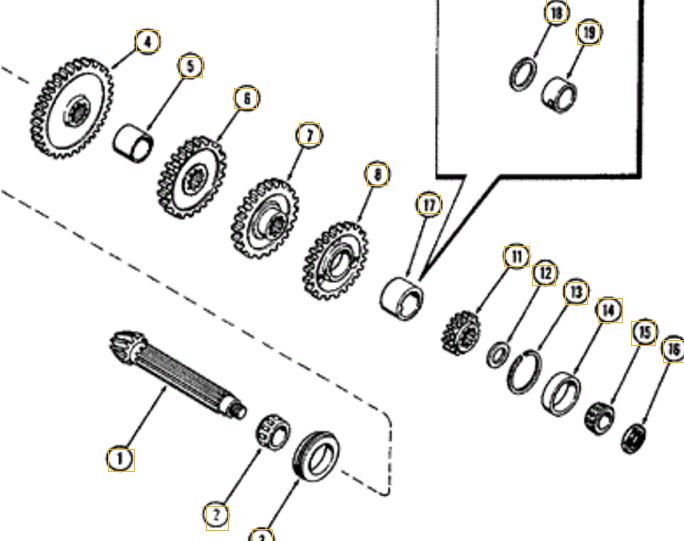

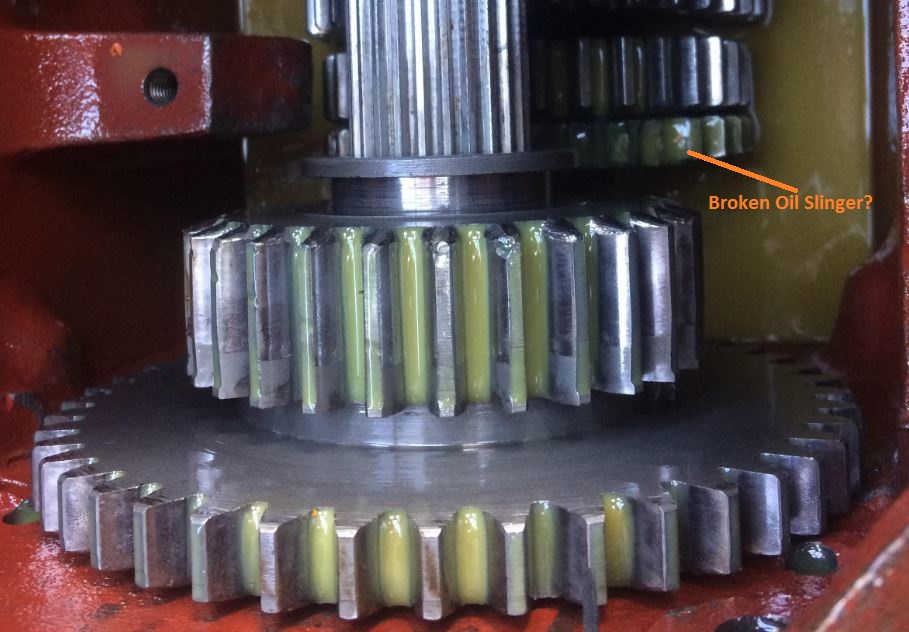

Last weekend I finally put her to work and started pulling some stumps out which was going very well. As I was using the loader to fill the holes back in, I heard a pop followed by a rattling noise. It was still driving, but I knew something wasn't right. I pulled the shift lever cover off to discover 5-6 teeth broken off what I believe is 1st gear on the countershaft. A lot of the other gears have the edges of the teeth chewed up/rounded, but nothing else is broken. I also noticed that there was a weld repair on one of the shift forks, which is suspicious to me.

Any ideas what might have caused the failure and the rounding of the teeth? I'm planning on splitting the tractor again between the powershuttle and the transmission, but I would really like to know what caused the failure before throwing more money at it.

Here's a couple pics to show what I'm referring to:

The gear that has broken teeth in the bottom of the second picture. It's the first gear towards the engine on the bottom shaft, it is quite a bit more narrow than most of the others.

Thanks in advance for any help or ideas.

-Luke

I recently purchased a 1969 580CK diesel with a power shuttle and 4 speed. I bought this machine not running with a broken ring gear on the flywheel. Over the course of a few weekends, I managed to split the tractor and replace the ring gear successfully. This is my first piece of heavy equipment so I learned a lot along the way.

Once the tractor was running I went through the machine and replaced all the fluids and filters, put a couple new tires on the rear, installed new gauges, re-wired the tractor and welded on a roll bar. Everything seemed to be working well with the exception of a couple leaky cylinders.

Last weekend I finally put her to work and started pulling some stumps out which was going very well. As I was using the loader to fill the holes back in, I heard a pop followed by a rattling noise. It was still driving, but I knew something wasn't right. I pulled the shift lever cover off to discover 5-6 teeth broken off what I believe is 1st gear on the countershaft. A lot of the other gears have the edges of the teeth chewed up/rounded, but nothing else is broken. I also noticed that there was a weld repair on one of the shift forks, which is suspicious to me.

Any ideas what might have caused the failure and the rounding of the teeth? I'm planning on splitting the tractor again between the powershuttle and the transmission, but I would really like to know what caused the failure before throwing more money at it.

Here's a couple pics to show what I'm referring to:

The gear that has broken teeth in the bottom of the second picture. It's the first gear towards the engine on the bottom shaft, it is quite a bit more narrow than most of the others.

Thanks in advance for any help or ideas.

-Luke