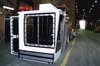

Greetings, gentlemen! I would like to beg your indulgence if I may and ask some questions that my sound elementary to many if not all of you. Being as I am not a logger, I freely admit my ignorance about how the job gets done. As I have posted before, I'm working on a scale model of the Madill 071 in 1/35 scale, and some pages back there are a few in-progress photos. The work continues, and I have reached a point where I have to think about rigging. I plan to display the finished model with the spar erect, and I know how the fixed guylines are attached, ends looped through ferrules and connected with turnbuckles & shackles to the anchor points. I understand how the powered guyline wires are run through their blocks at the end of the spar. What I don't have a handle on are these questions:

How are the powered guyline wires typically terminated? With a loop and ferrule like the fixed lines, left bare, looped and secured with several cable clamps , or something else?

What are the usual terminations on the Skyline, Main, and Haulback lines? Or are the ends left bare?

My intent is to show the three yarding lines dangling down from their sheaves, ready to be run out to wherever they are needed. There is a twist, however. I will have the ability to display the spar down in transport mode as well, and that leads to another question: How are all these lines usually secured for transport? My only reference is from yarder #70097 that I photographed at Tillamook a few years ago. At the time, it was semi-derelict and I don't trust that the way the various rusty lines were draped reflected an in-service configuration. Any guidance you can offer would be most welcome.

Finally, let me ask this: If you know of 071 yarders in Oregon or Washington that can be photographed, please contact me here or off-board at gtbuechler@Hotmail.com. I've decided that I would like to write a book on these machines geared to other modelers, so I would like to document as many surviving examples as I can.

Thanks!

Greg

How are the powered guyline wires typically terminated? With a loop and ferrule like the fixed lines, left bare, looped and secured with several cable clamps , or something else?

What are the usual terminations on the Skyline, Main, and Haulback lines? Or are the ends left bare?

My intent is to show the three yarding lines dangling down from their sheaves, ready to be run out to wherever they are needed. There is a twist, however. I will have the ability to display the spar down in transport mode as well, and that leads to another question: How are all these lines usually secured for transport? My only reference is from yarder #70097 that I photographed at Tillamook a few years ago. At the time, it was semi-derelict and I don't trust that the way the various rusty lines were draped reflected an in-service configuration. Any guidance you can offer would be most welcome.

Finally, let me ask this: If you know of 071 yarders in Oregon or Washington that can be photographed, please contact me here or off-board at gtbuechler@Hotmail.com. I've decided that I would like to write a book on these machines geared to other modelers, so I would like to document as many surviving examples as I can.

Thanks!

Greg